COMPANY

A Dynamic, Globally Renowned Producer of Advanced Control Valves and Systems based on Innovation and Reliability

The Company

Since 1971 Mil Inbal Valves Ltd has been developing, designing, manufacturing and providing advanced Automatic Control Valves and Systems for a wide range of industries around the world. Leading players in the offshore, oil refining, petrochemical, oil, gas and chemical storage, marine, aircraft hangars and power generation markets count on Mil Inbal Valves for a comprehensive array of automatic control valves engineered for specific industrial fire protection systems.

Innovation in research and development, as well as superior product design and proven reliability, have established Mil Inbal Valves Ltd as a globally renowned name in its field. The company’s focus and involvement in product support and customer training have been instrumental in building its global success and reputation as the world leader in advanced Automatic Control Valves, Systems, and Consultation for implementation of solutions. With worldwide sales offices and thousands of product installations in more than 50 countries around the globe, Mil Inbal Valves is experiencing unprecedented growth as it realizes its mission to provide the world’s most advanced control solutions.

Company Background

Part of the MIVAL Group – Mil Inbal Valves Ltd is the newest generation in a group of companies that evolved from the Zvi Blass, Company founded in 1949, (now a major distribution organization, representing on a sole basis, the world’s leading brands in the valve industry). Originally focused on the production of pipe equipment, in 1961 Zvi Blass began to manufacture Diaphragm Actuated Control Valves which quickly became their main product line. In 1971 Mil Inbal Valves Ltd was born as a separate business entity concentrating on the development, design and production of Automatic Control Valves.

The company’s reliance on tradition, yet constant anticipation of the future of Control Valve Technology, has undoubtedly contributed to its international achievements.

Product Line

An extensive range of Automatic Control Valves, produced in a wide array of sizes and high-grade alloys, characterizes Mil Inbal Valve‘s product line. Typical applications handled by the company product line include: fire protection systems, water distribution, water treatment and water consuming industries such as steel, paper mills, air conditioning and irrigation systems.

In 1974 Mil Inbal Valves revolutionized the control valve industry by introducing the world’s first three-part automatic control valve, the Inbal Valve, named after a fourth generation member of the company’s founding family. Featuring No Moving Mechanical Parts, the Inbal line is virtually maintenance free, suitable for a wide variety of industries and patented around the world.

The Mil Inbal Valves product line is listed by Underwriters (UL) as Deluge Valve and Pressure Relief Valve, approved by Factory Mutual (FM) as Deluge Valve, Pressure Control Deluge Valve, Dry Pipe Valve, Pressure Reducing Valve, Pressure Relief & Sustaining Valve and Refrigerated Area System and by Schadenverhutung (VDS) as Deluge Valve.

In addition the Inbal Valves are Type approved by American Bureau of Shipping (ABS), Bureau Veritas (BV), Det Norske Veritas Germanischer Lloyd (DNV GL), Llyod’s Register (LR) and Russian Maritime Register of Shipping (RMRS).

Engineering

Mil Inbal Valves Engineering Department is in charge of research and development of new products and design of Systems according to the Customer’s needs including Valve Sizing, Blast & Green water pressure and reliability (SIL) calculations.

Mil Inbal Valves Document Control is involved in the project right at the beginning from the estimation stage and then with direct contact of Customer during design, production & Inspection, coordinates to provide all the documentation and manufacture the product meeting the specifications of the project.

Quality Assurance & Control

Quality Assurance (QA) and Quality Control (QC) are priority processes continuously implemented at all stages of manufacturing: incoming inspection, process control and final inspection & testing.

Mil Inbal valves Quality Control System is approved as complying with ISO 9001 standard since 1991.

Each Order on receipt is evaluated By Mil Inbal Valves QA and accordingly quality plan and procedures are generated to meet the Customer’s and Project quality requirement.

Health, Safety & Environment

Mil Inbal Valves constantly endeavors for the improvement of the health and safety standard of its workers and is a certified Occupational Health and Safety Management System according to ISO 45001.

Also the Company is a certified Environmental Management System according to ISO 14001 and focuses on achieving better environmental conditions.

Testing Facilities

Full Flow Test Facility Demonstrating The Actual Pressure And Flow Conditions Of Each Specific Valve Tag As Specified By The Customer.

Test Bench

Test Rig Pump Station

Test Bench Overview

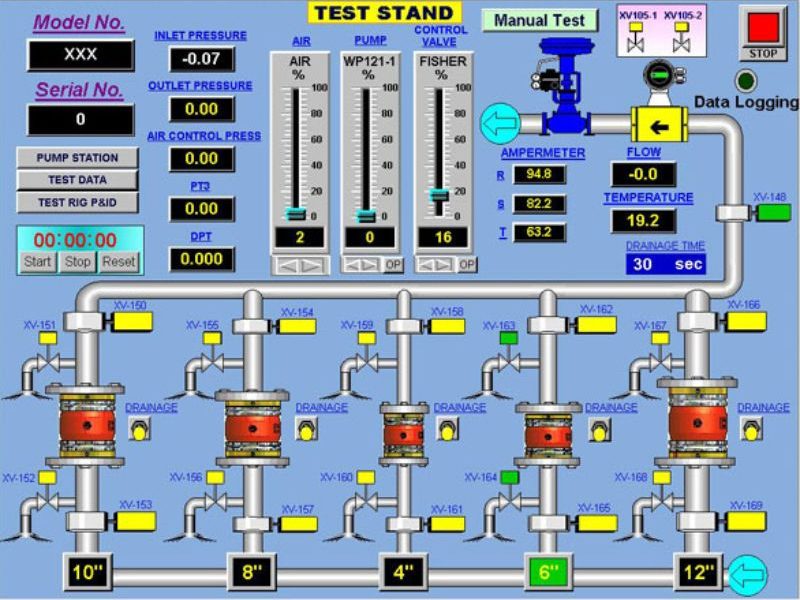

Test Bench HMI Screen

Life Cycle test Facility

Small Diameter Products Test Facility For Testing Pressure & Flow

Valve Control Trim Test Facility

HYDROSTATIC, LEAKAGE & CONTROL TEST FACILITY