Inbal Valves embody a breakthrough in the conceptual design of automatic water control valves. Developed from basic principles, they are free of limitations imposed by the human hand, which characterize conventional control valves such as clapper, latch, or diaphragm actuated types. The major concept that led to the development of the Inbal Valve is the N.M.M.P. (No Moving Mechanical Parts), a significant feature in fire protection systems where long life of reliable operation is considered the first criterion in selecting equipment, particularly control valves.

The Inbal Valves are approved by Factory Mutual (FM), VdS Schadenverhütung, Type Approved by Lloyd’s Register, American Bureau of Shipping (ABS), Det Norske Veritas Germanischer Lloyd (DNV GL) and Bureau Veritas (BV) and listed by Underwriter’s Laboratories (UL).

INBAL VALVE

The Inbal Automatic Water Control Valve series 700D is a pressure operated, sleeve actuated, axial valve, designed from basic concepts, with a built-in actuator to function as control valve in fire protection system.

The Inbal Valve, designed for control valve service from basic concepts, utilizes a built-in sleeve actuator.

Upon removal of the control pressure the Inbal Valve opens instantaneously, yet very smoothly, to prevent any water hammer in the piping system.

The Inbal Automatic Water Control Valve utilizes the unique N.M.M.P. (No Moving Mechanical Parts) design. The only moving part when the Inbal Valve operates, is the reinforced sleeve which forms a drip-tight seal with the corrosion resistant core. The Inbal design also prevents false operation due to transient surges in water supply pressure.

As standard, Inbal Valves are made of Ductile Iron ends and Steel housing – both epoxy coated. A large variety of optional materials including Cast Steel, Stainless Steel, Bronze, Nickel-Aluminum- Bronze, and Titanium are available from stock. Optional coating such as high built epoxy or Halar ® can be supplied upon request.

The standard material Inbal Valve is rated to 300 psi (21 bar) and requires a minimum line pressure of 20 psi (1.5 bar) for operation.

To Explore the structure of the Inbal Valve in different views and open & close positions.

Click the Start Button

Press the Cursor and move for different angle views.

Then click the Sectional View, Transparent View and the Open and Close position Buttons

ON / OFF INBAL VALVE

In standby closed position the Inbal Valve and the control chamber is pressurized from the Inlet side.

Upon removal of the control pressure the Inbal Valve opens instantaneously, yet very smoothly.

To View the ON/OFF working of the Inbal Valve

- Click on the Start Button

- Then click the Open and Close button.

To view the Inbal Pressure Control Monitor Valve working

Click on the Start Button

Then click the Open Valve button.

Click the Increase pressure button

Click the Decrease pressure button

Click the Close Valve button

PRESSURE CONTROL

MANUAL RELEASE, INBAL PRESSURE CONTROL MONITOR VALVE

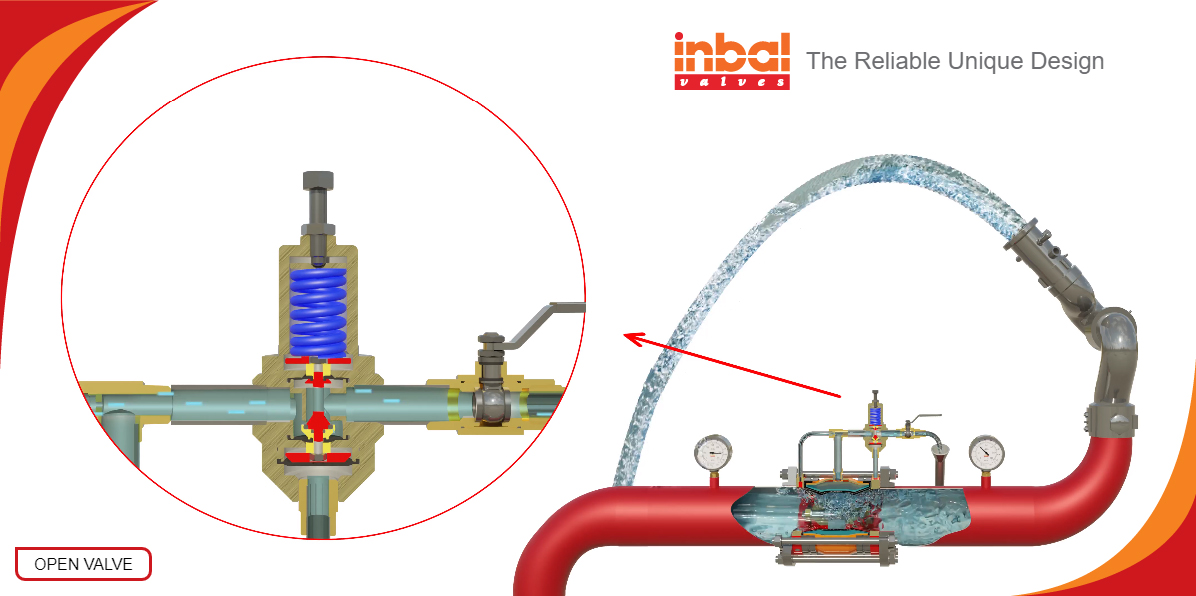

This system consists of a pressure control valve. This type of system is used when pressure control and flow control features are needed.

The Pressure Control Inbal Monitor Valve, when in operation, automatically controls the Outlet pressure to a pre-set delivery pressure which remains steady and unaffected by the variations or fluctuations of the Inlet Line pressure.

Turning the pressure control Pilot Valve Adjusting Screw clockwise increases downstream pressure and counter-clockwise decreases the downstream pressure.

To view the Inbal Deluge Valve working

Click on the Start Button

Then click the Fire button.

Click the Reset button

ELECTRICAL ACTUATION

ELECTRICAL ACTUATION, INBAL DELUGE VALVE

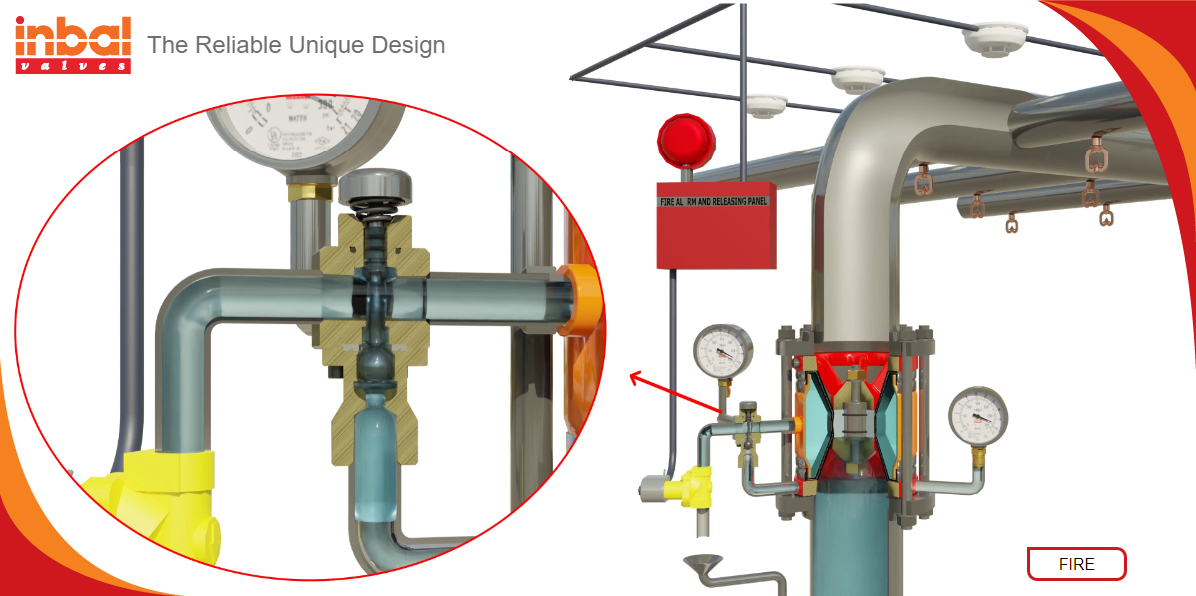

The Inbal Deluge Valve is actuated when the electric detection system sends an electric signal to activate the Solenoid Valve.

When the Solenoid Valve is actuated, the Inbal Deluge Valve opens and water flows from all open Sprinklers.

Once the Inbal Deluge Valve operates, it latches in an open position, preventing the Inbal Deluge Valve from closing even if the solenoid valve returns from open to closed position. The Inbal Valve will close only when the Resetting is done.

As soon as the releasing system and the sprinkler piping are reset, the Inbal Deluge Valve resetting is merely done by activating the reset knob.

PNEUMATIC ACTUATION

PNEUMATIC ACTUATION, INBAL PRESSURE CONTROL DELUGE VALVE

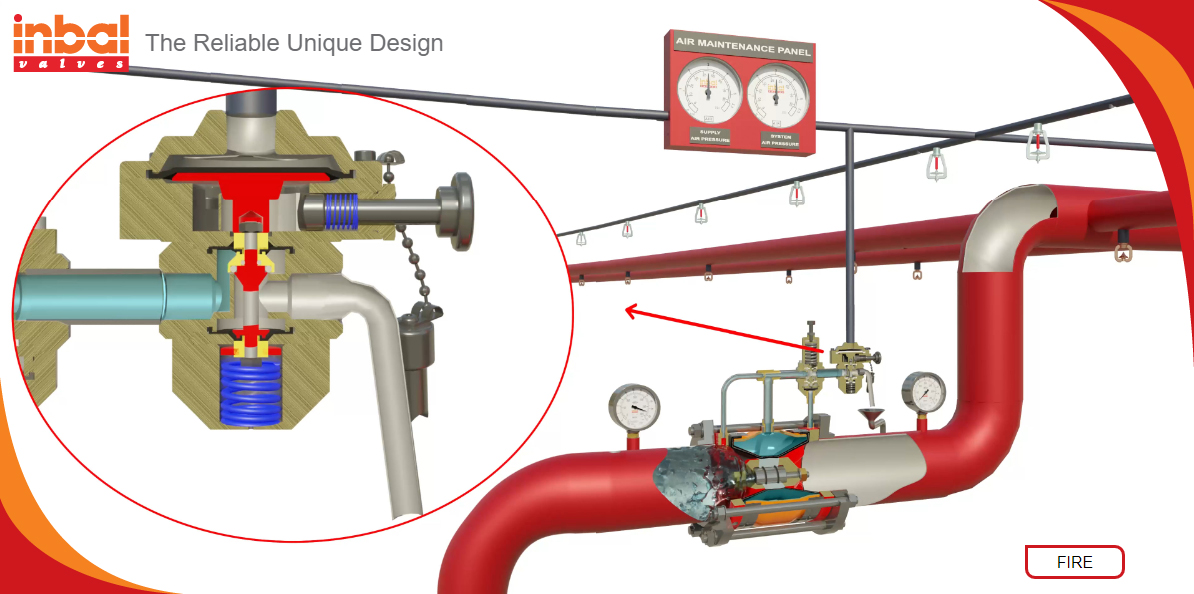

The Inbal Deluge Valve has the ability to control the flow into the protected area by controlling the downstream pressure. When one or more of the sprinkler heads located on the pilot line fuses, the Inbal Deluge Valve opens and water flows from all open nozzles.

The Pressure Control Inbal Deluge Valve, when in operation, automatically controls the Outlet pressure to a pre-set delivery pressure which remains steady and unaffected by the variations or fluctuations of the Inlet Line pressure.

Turning the pressure control Pilot Valve Adjusting Screw clockwise increases downstream pressure and counter-clockwise decreases the downstream pressure.

Once the Inbal Deluge Pilot Valve operates, it latches in an open position, preventing the Inbal Pressure Control Deluge Valve from closing even if the open releasing dry pilot line closes. The Inbal Valve will close only when the Resetting is done.

As soon as the releasing system and the sprinkler piping are reset, to reset the Inbal Deluge Valve, pull the Deluge Pilot Valve Latching mechanism Reset Knob and insert the Resetting Indicator to hold the Reset Knob @ a pulled out position.

Open the air supply source Valve. As soon as the air /pneumatic pressure exceeds the level required by the Deluge Pilot Valve equipped w/ Latching mechanism for “set” position, the Resetting Indicator falls off hung by the Security Chain.

To view the Inbal Deluge Valve working

Click on the Start Button

Then click the Fire button.

Click the Increase Pressure button

Click the Reset button